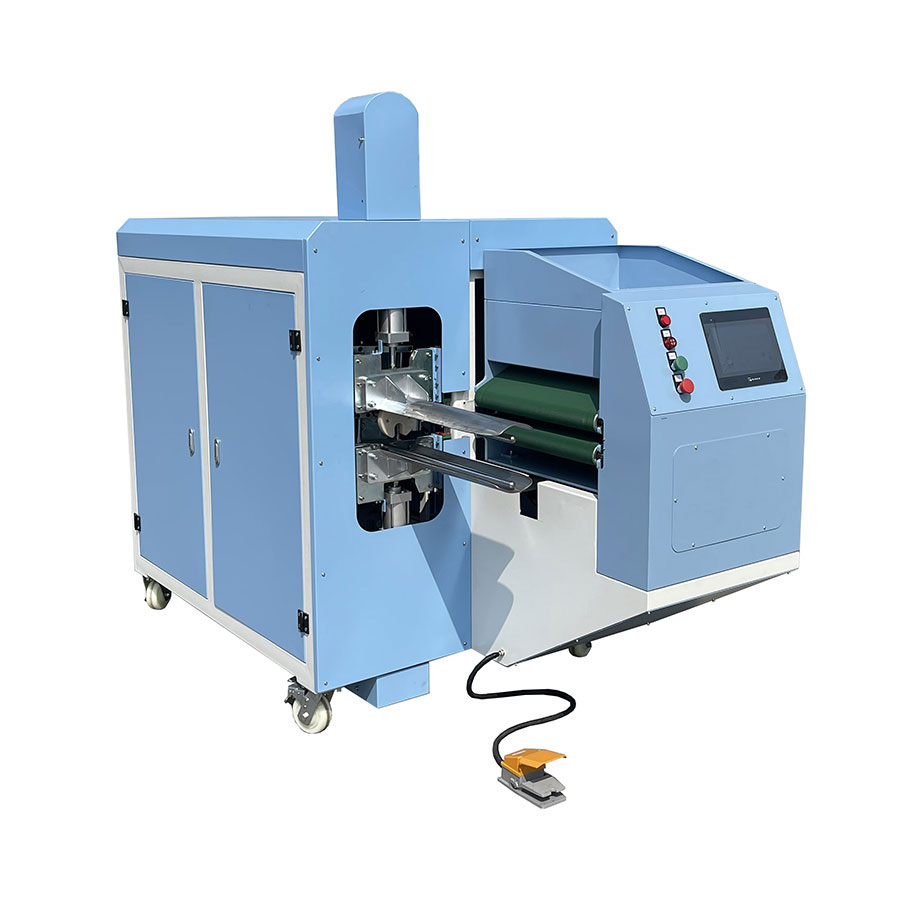

Automatic weighing filling machine KWS688-2

Specifications

|

Automatic Weighing Filling Machine KWS688-2A |

|||

| Overall Dimension: 2000*2300*2230mm (4.5㎡) | Packing size/Gross Weight:6.2CBM/800KG | ||

| Voltage/Power | 220V 50HZ/1.8KW | Accuracy Class | Down±0.1g /Fiber ±0.3g |

| Storage box Size | 2275*900*2230mm | Storage Capacity | 25-45kg |

| Weighing machine Size/1Sets | 1800*580*1000mmt |

Filling Range |

0.5-35g(Single weighing range) |

| Dedicated Workbench | (Optional) | Filling Port | Two Heads (4 Scales) |

|

Weight |

670kg |

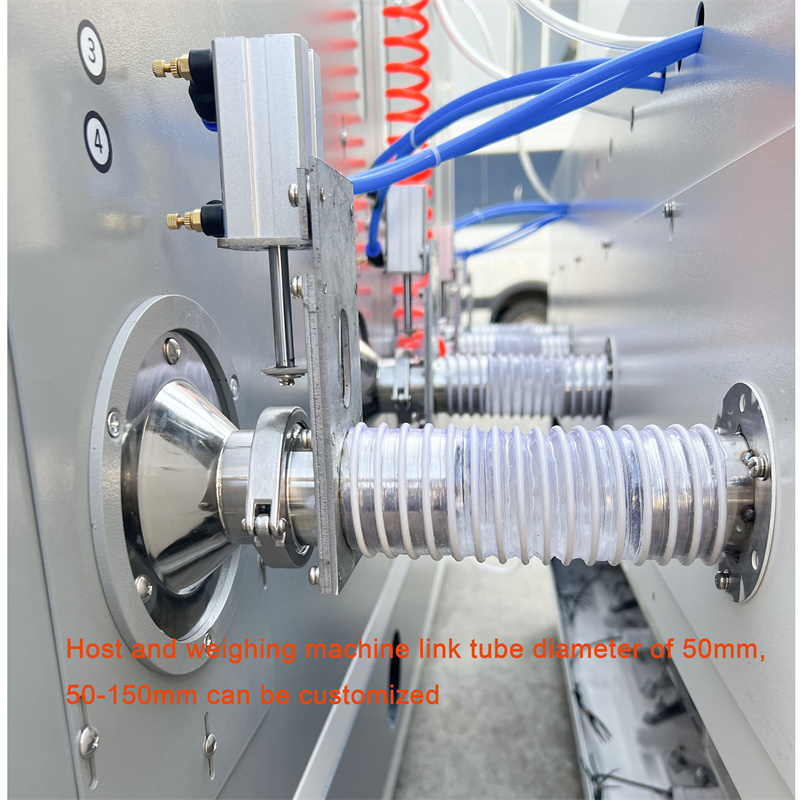

Filling Port Size/2sets | Φ16/19/25mm×Length450mm |

|

Display Interface |

10“HD Touch Screen |

Filling Speed |

30-60PCS/min(fabric piece≤20g) |

|

Auto Feeding System |

Including feeding fan |

Heavy Duty Allocation Deduction |

YES |

|

USB Data Import Function |

YES |

Air Pressure |

0.6-0.8Mpa (Need air compressor≥11kw,not included ) |

|

Automatic Weighing Filling Machine KWS688-4 |

|||

| Overall Dimension: 3000*2300*2230mm (7㎡) | Packing size/Gross Weight:7.8CBM/980KG | ||

| Voltage/Power | 220V 50HZ/2.8KW | Accuracy Class | Down±0.1g /Fiber ±0.3g |

| Storage box Size | 2275*900*2230mm | Storage Capacity | 25-45kg |

| Weighing machine Size/2Sets | 1800*580*1000mmt |

Filling Range |

0.5-35g(Single weighing range) |

| Dedicated Workbench | (Optional) | Filling Port | Four Heads (8 Scales) |

|

Weight |

800kg |

Filling Port Size/2sets | Φ16/19/25mm×Length450mm |

|

Display Interface |

10“HD Touch Screen |

Filling Speed |

60-120PCS/min(fabric piece≤20g) |

|

Auto Feeding System |

Including feeding fan |

Heavy Duty Allocation Deduction |

YES |

|

USB Data Import Function |

YES |

Air Pressure |

0.6-0.8Mpa (Need air compressor≥11kw,not included ) |

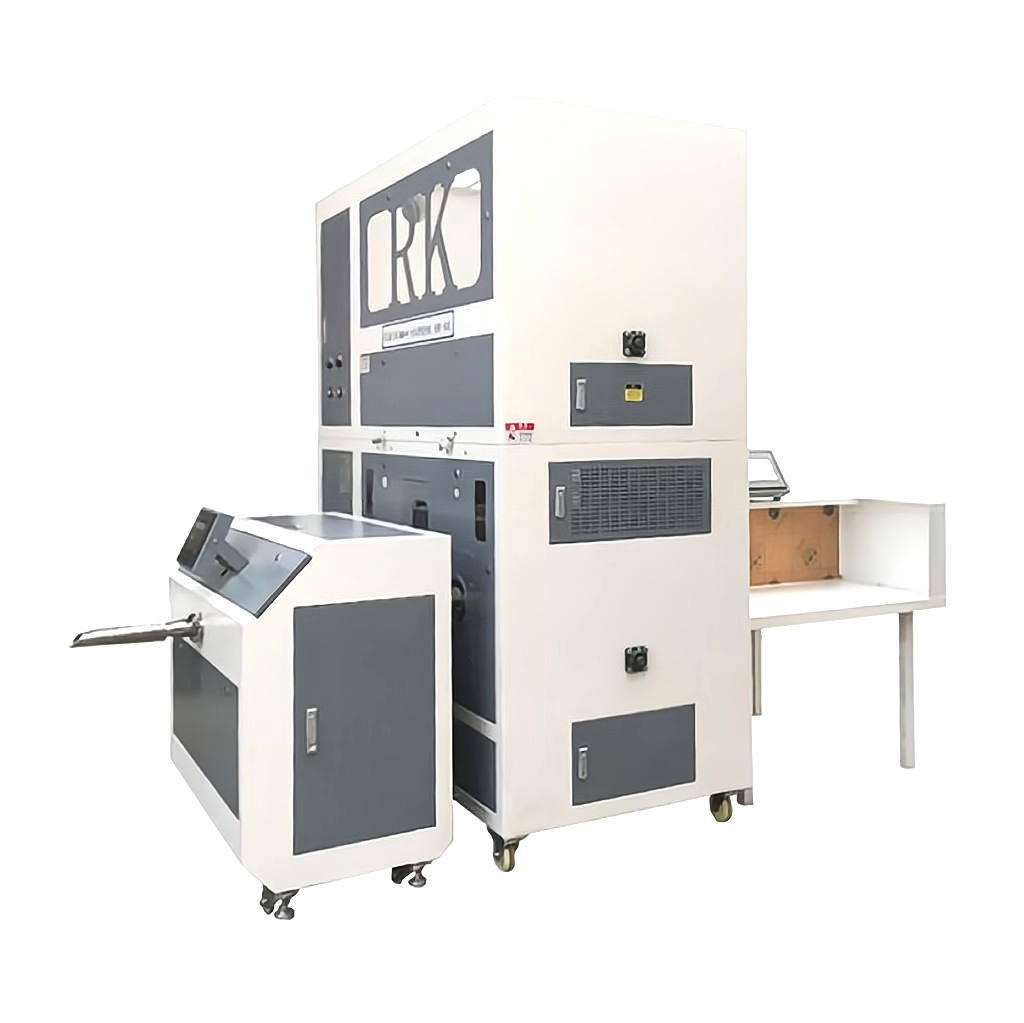

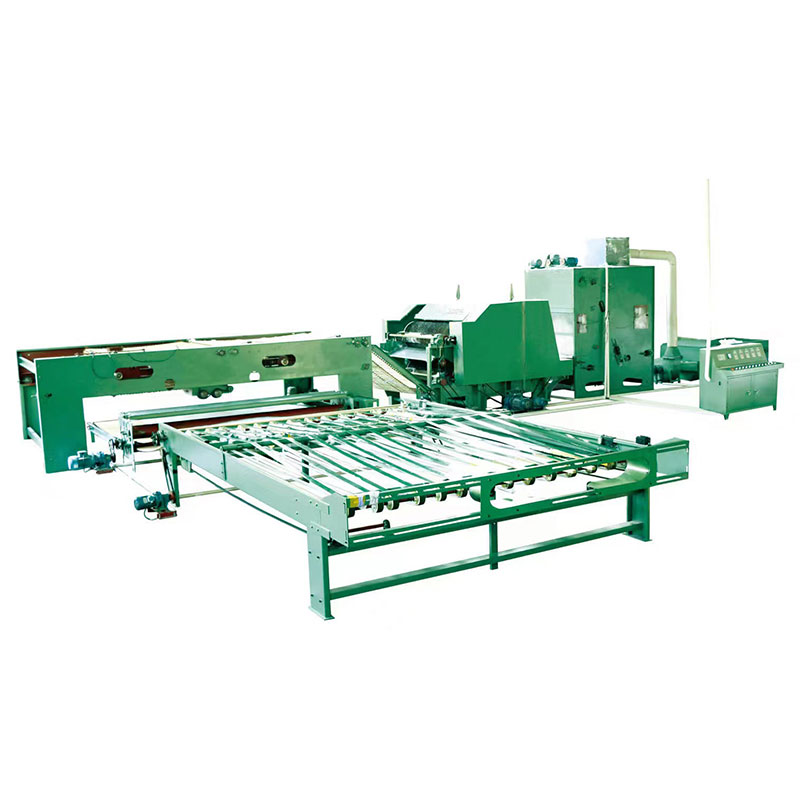

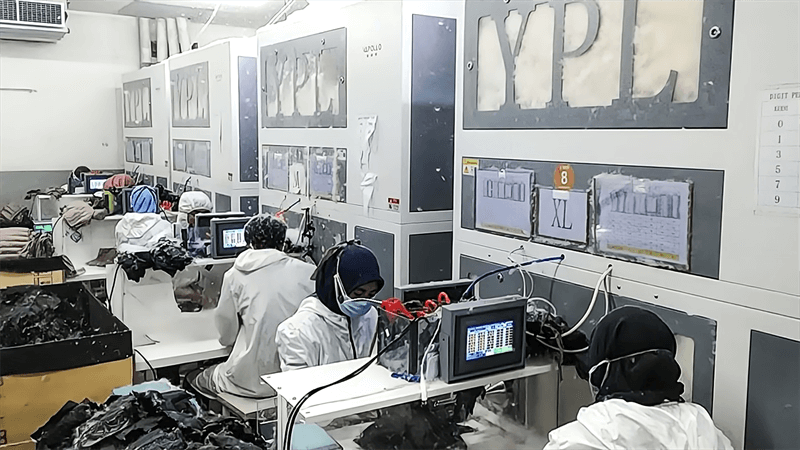

Product display

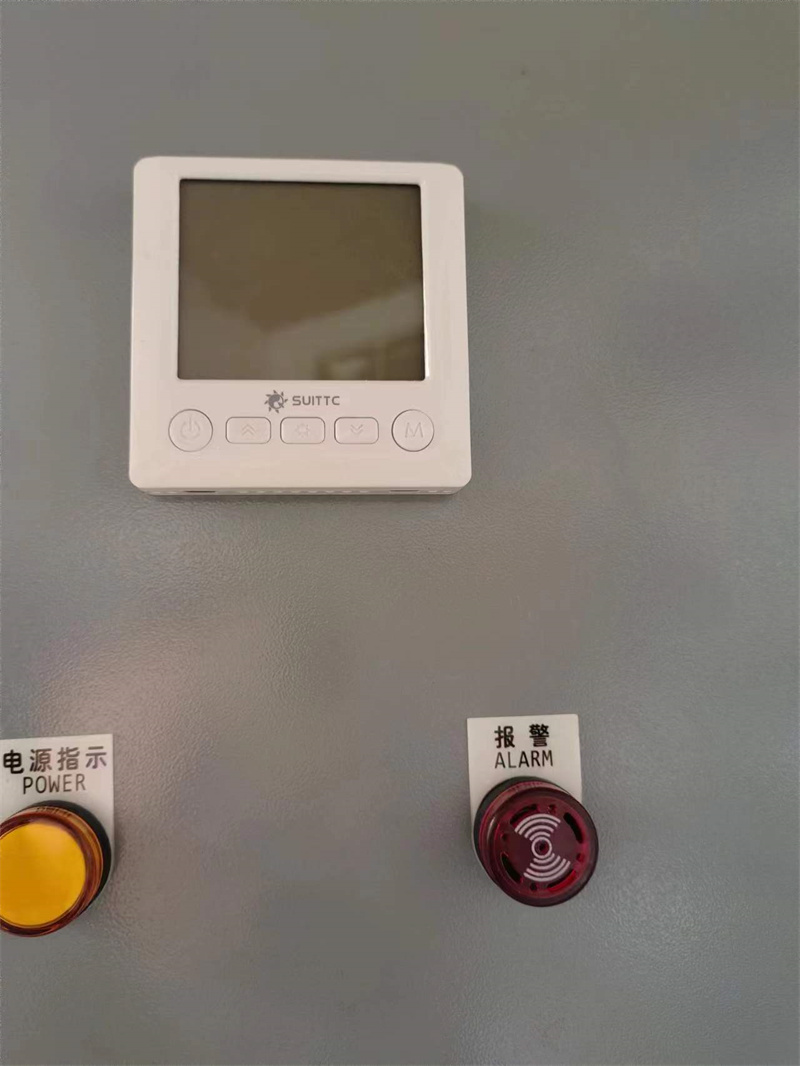

·The electrical components are all internationally renowned brands, and the accessories are in accordance with the "International Electrotechnical Standards" and comply with the safety regulations of Australia, the European Union and North America.

·The standardization and generalization of parts are high, and the maintenance is simple and convenient.

·The sheet metal is processed by advanced equipment such as laser cutting and CNC bending. The surface treatment adopts electrostatic spraying process, which is beautiful in appearance and durable.

Product display

①The electrical components are all internationally renowned brands, and the accessories are in accordance with the "International Electrotechnical Standards" and comply with the safety regulations of Australia, the European Union and North America.

②The standardization and generalization of parts are high, and the maintenance is simple and convenient.

③The sheet metal is processed by advanced equipment such as laser cutting and CNC bending. The surface treatment adopts electrostatic spraying process, which is beautiful in appearance and durable.

Our Solution

This equipment can be filled with 50/60/70/80/90 Duck down, Goose down, Balls fiber and Chemical fiber, et

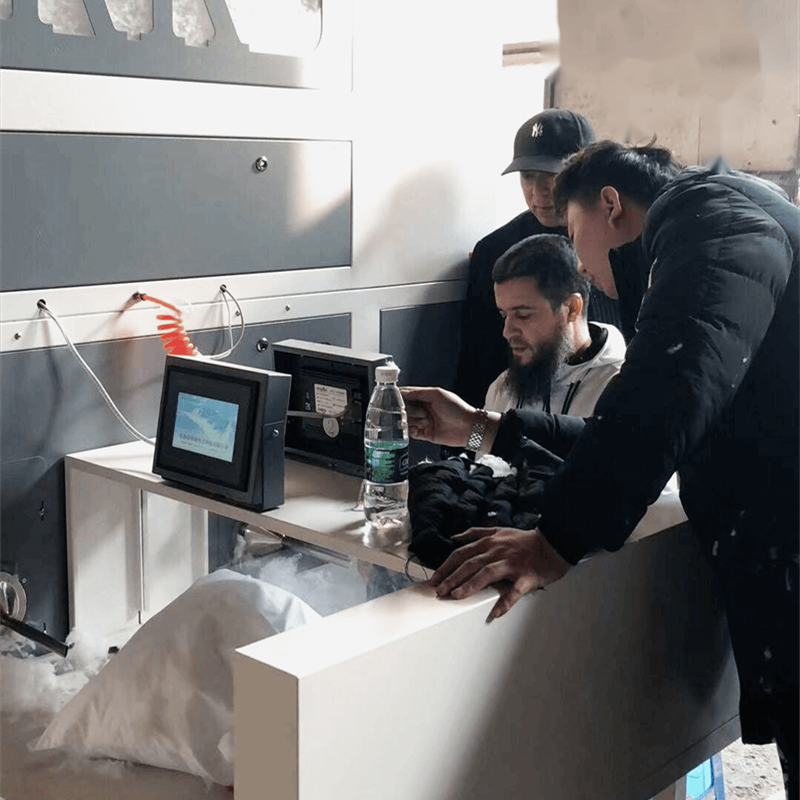

Three steps to show you how it works?

①Click "one button feeding" on the touch screen, the fan will start and automatically suck the down or chemical fiber into the storage box.

②Click "Recipe Edit" on the touch screen ,enter the number, name, and target weight in turn,and then start the system.

③Put the fabric piece to the filling nozzle and hold it in the right way, then step on the foots witch ,the target weight material is filled into the fabric piece evenly.

Our Solution

According to the requirements of customers,Install remove static electricity, disinfection and drying functions.(Additional charge for additional parts)

What People Say

Lead time

Where to Sell

Our products are all over the world and exported to North America, Canada, Russia, Poland, Turkey, Ukraine, Vietnam, Kyrgyzstan and many countries in Asia.

Escort your filling process with our strength!

Qingdao Kaiweisi Industry&Trade Co.,Ltd

Add:Chaoyangshan Road ,Huangdao,Qingdao,China

Tel:+86-0532-86172665

Mob:+86-18669828215

E-mail:kivas@qdkws.com

Web:www.qdkivas.com

www.kaiweisi.en.alibaba.com