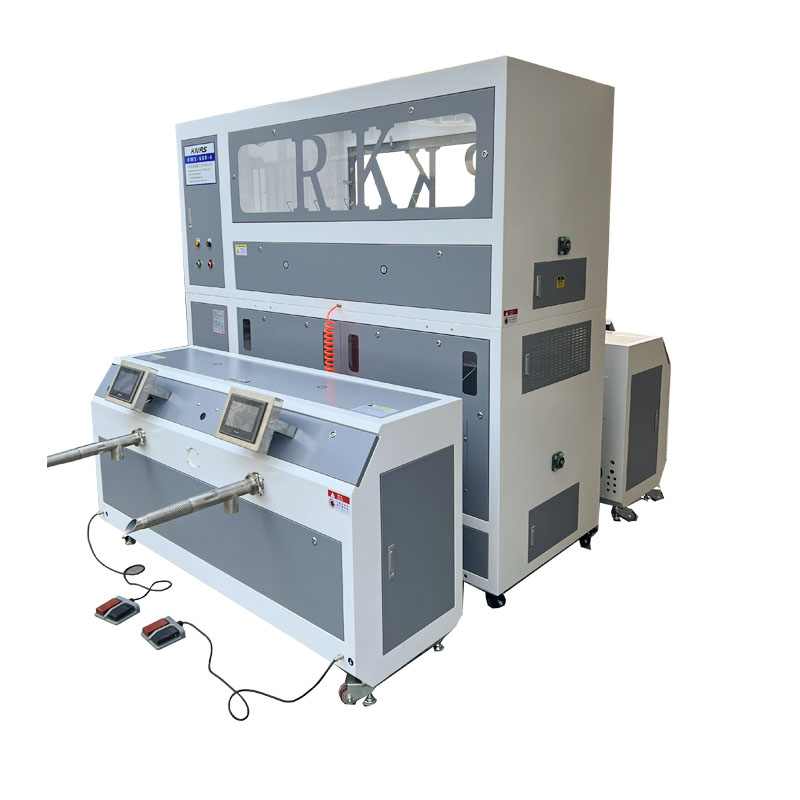

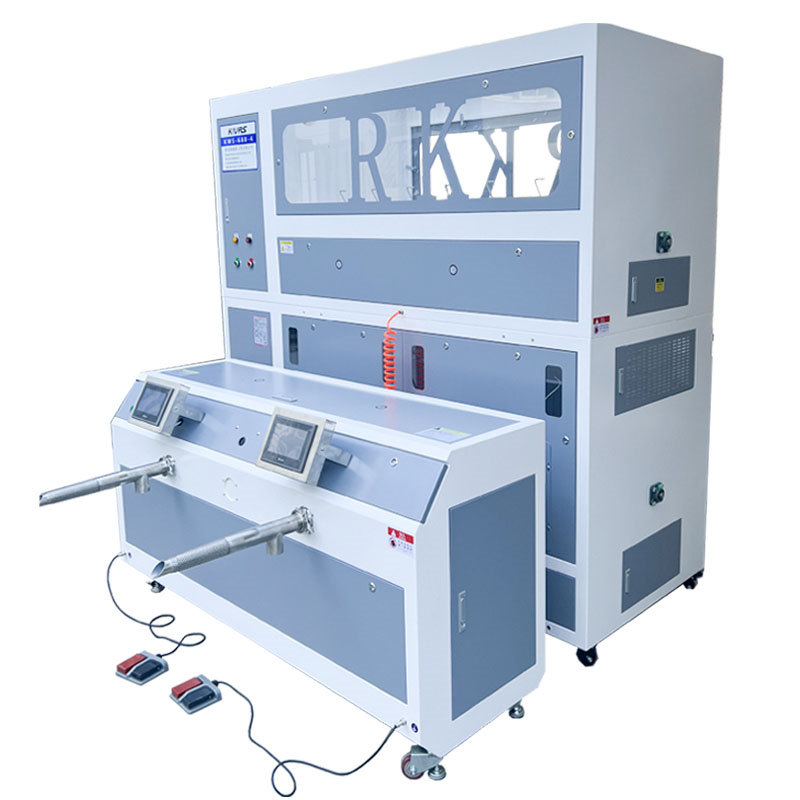

High Precision Filling Machine KWS6901-2

Application:

·Applicable materials: 3D-7D high fiber cotton, wool and cotton (length 10-80mm)\elastic latex particles, high elastic broken sponge particles, feather, cashmere, wool and the mixture involved.

· Applicable products of this machine: quilts, pillows, cushions, outdoor sleeping bags and outdoor thermal products.

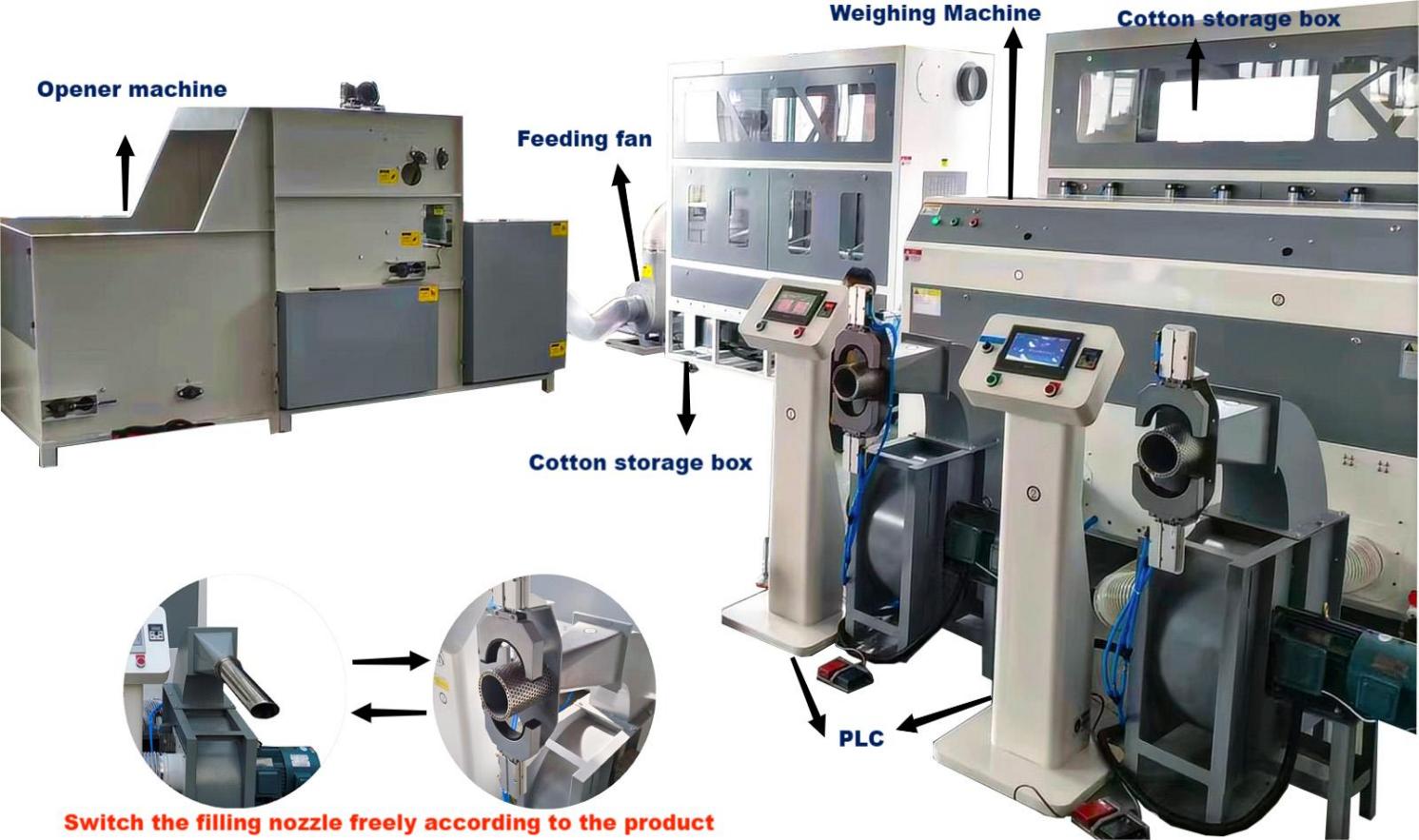

Functional display

This machine is equipped with three sets of filling ports, which can meet various styles.The filling requirement of large gram weight. A set of fixture type filling port, mainly used for filling pillow core, pillow and other products. Two sets of different diameters and length of straight tube filling nozzle, φ65mm * 70cm can fill feather duvet, φ90mm * 25cm can be filled with full format pillow core, cushion,sofa pillow and other products.

Machine Parameters

|

Model |

KWS6901-2 |

Filling nozzls |

2 |

|

| Machine Size:(mm) | Package Size:(mm) | |||

| Main Body Size | 2400×900×2200×1 set | Main Body and Independent table |

2250×900×2300×1pcs |

|

| Weighing Box Size | 2200×950×1400×1set | |||

| Filling Fan | 800×600×1100×2sets |

Weighing Box |

2200×950×1400×1pcs

|

|

| Independent Table | 400×400×1200×2sets |

Filling Fan and Feeding Fan |

1000×1000×1000×1pcs |

|

|

Feeding Fan |

550×550×900×1set |

Area Covered

|

5000×3000 15㎡

|

|

|

Net Weight

|

1305kg |

Gross Weight

|

1735kg |

|

|

Filling Range |

10-1200g |

Cycle Number |

2 times |

|

|

Storage Capacity |

20-50kg |

USB Data Import Function |

Yes |

|

|

Accuracy Class |

Down±5g /Fiber ±10g |

Heavy Duty Allocation Deduction |

Yes |

|

|

Auto Feeding System |

Optional |

Filling Speed |

300g pillow:7pcs/min |

|

|

Air Pressure |

0.6-0.8Mpa |

Voltage/Power |

380V50HZ/10.5KW |

|

Environment Requirement

·Temperature: Per GBT14272-2011

requirement,filling test temperature is 20±2℃

·Humidity: Per GBT14272-2011, the humidity of filling test is 65±4%RH

·Air volume≥0.9㎥/min.

·Air pressure≥0.6Mpa.

·If the air supply is centralized, the pipe should be within 20m,the diameter of the pipe should not be less than 1 inch. If the air source is far away, the pipe should be bigger accordingly. Otherwise, the air supply is not enough, which will cause filling instability.

·If the air supply is independent, it is recommended to have11kW or more high-pressure air pump(1.0Mpa).

·Adopt high-precision sensors, the accuracy value is adjustable within 1 gram; adopt super large hopper, the single weighing range is about 10-1200 grams, which solves the problem that filling large grams of products in the home textile industry has been unable to accurately quantify.

·Oversized storage box can store 50KG materials at one time, saving the feeding time. Optional unmanned feeding system,automatically feed when there is no material in the storage box, and automatically stop when there is material.

·It solves the problem of multi-purpose of a single machine, and can be compatible with filling 3D-17D high fiber cotton, down and feather pieces (10-80MM in length), flexible latex particles, high elastic sponge scraps, wormwood, as well as the mixture involved, fully improving the cost performance of the equipment.

·Modular configuration of filling nozzle: θ 60mm、 θ 80mm、 θ 110mm, can be replaced without any tools according to the product size.

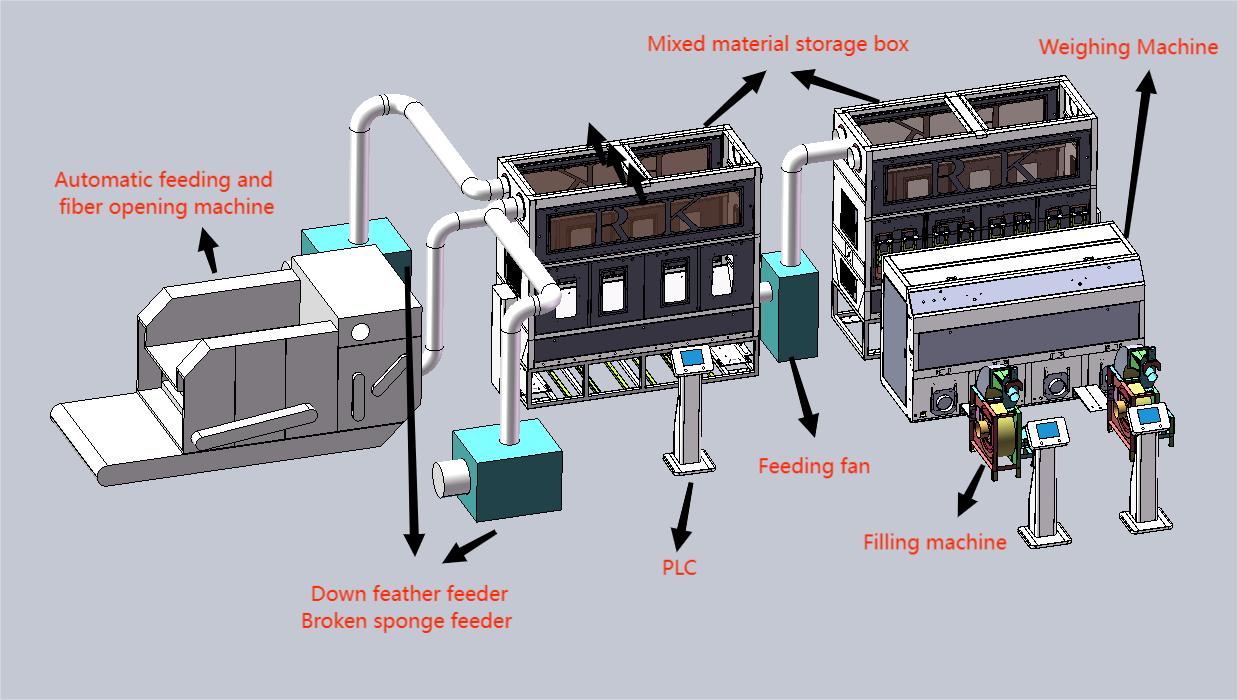

·This machine can be linked with streamline equipment such as bale-opener, cotton-opener, mixing machine, and can realize production automation.

·Adopt PLC programmable controller and high-precision weighing module, achieving more accurate and efficient production capacity.

·One person can operate two filling mouths at the same time, reducing labor and saving costs.

Production line display: